March 13, 2020

Occasionally, a simple thing like a guitar pedalboard finds a way to become a system of great complexity. For an engineer, this Dual Pedalboard was complex due to unusual design requirements that had to be coordinated into a simple, manufacturable, and cost-effective item that fits the customers needs. The end product exceeded the design requirements, most notably in visual appeal, and rigidity.

The first iteration consisted of joining two equally sized pedalboards together by a door hinge on the inside corner. The hinge would act as a flex-point for cables, made it simple to merge the two sections together for transportation. This design however had several errors.

In order to properly fasten a heavy-duty hinge to the pedalboard, the pedalboard would have to be 2-3” in height. This height would not only be cumbersome for pedal operation but would greatly limit the height of pedals that could fit in the customers case. Additionally, when the hinge was closed, there would be a large, potentially damaging, torque on it’s joint if the pedalboard was incorrectly handled or on uneven ground.

The next design consisted of using a hole-and-pin approach. A large metal rod would be used to transfer torque between each pedalboard section for transportation. This idea was conceived by observing the locking mechanisms on fence gates.

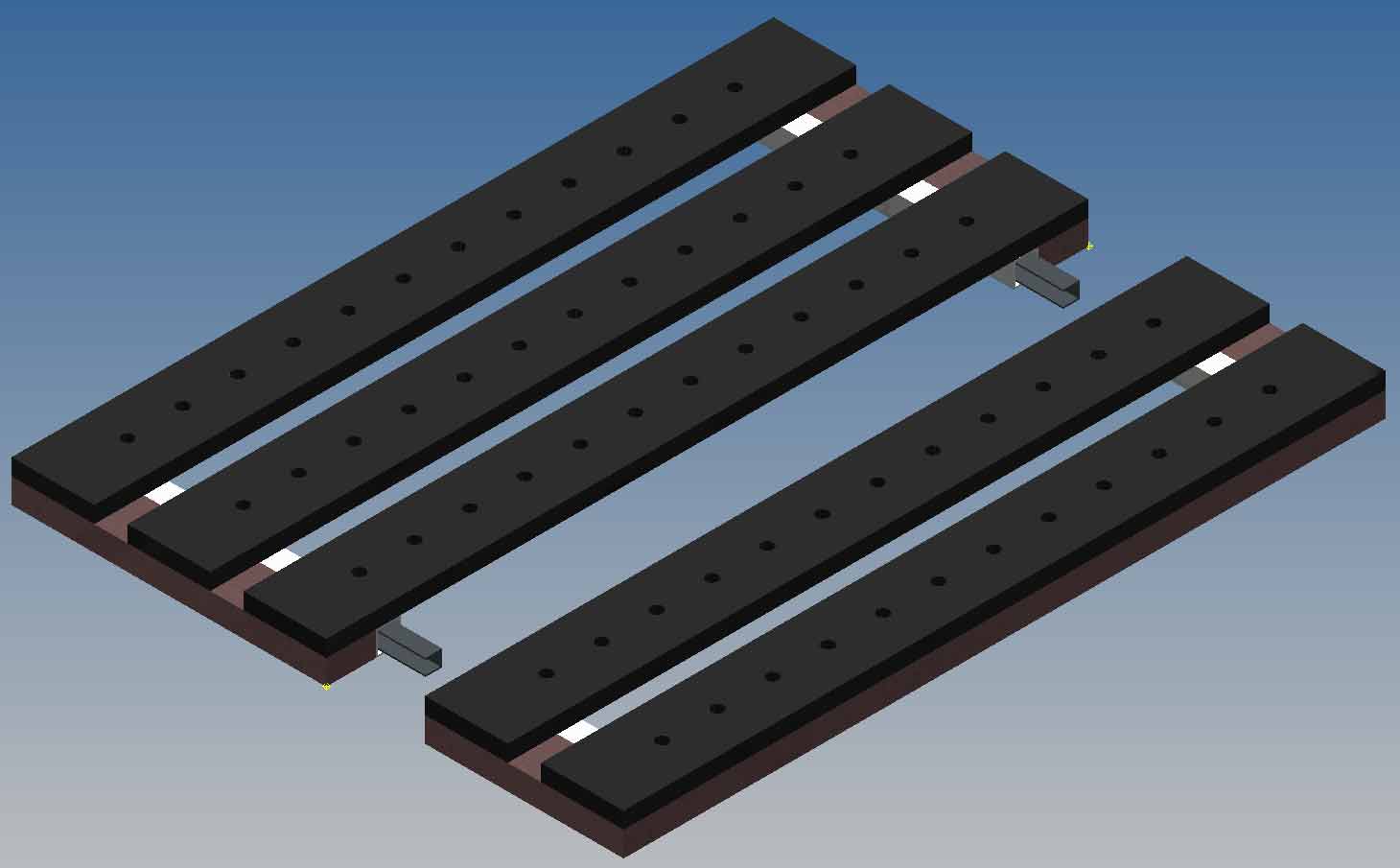

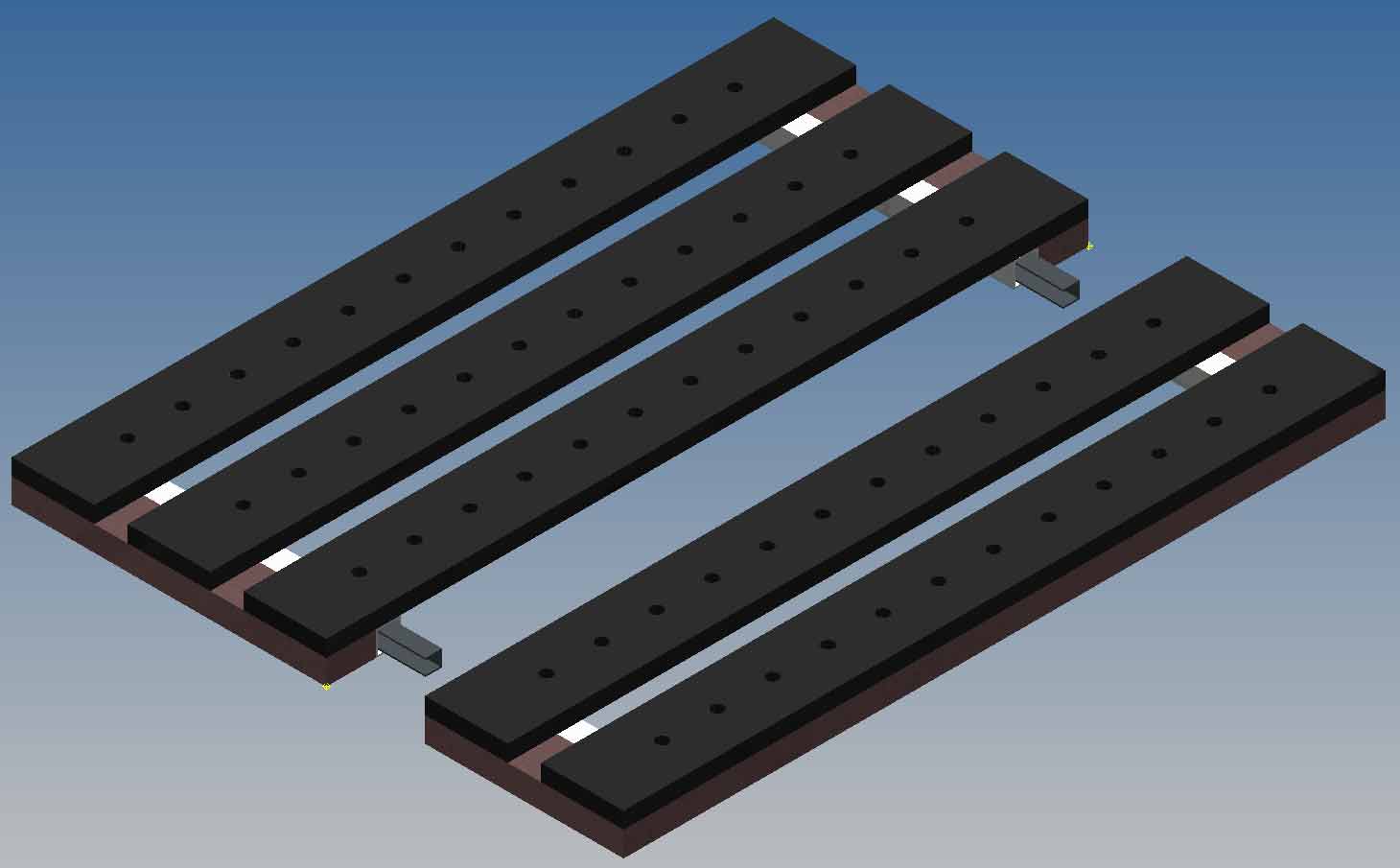

Once the customer’s requirements were met a final design was chosen. In order to affix the two sections together, each individual pedalboard was equipped with square aluminum tubing underneath the top panels and attached directly to the frame. A piece of U shaped aluminum was cut and inserted into the square tubing. One pedalboard section is 6'' in depth whereas the other is 9-1/2”. The U shaped rod is equal in length to the larger depth. This way, when the U-rods are in the shorter pedalboard’s square tubing, they extend 3” outward. In this position they are held in place magnetically. The rods can then be simultaneously in both sections of pedalboards to transfer torque. There is enough translational friction so that no further hardware to hold the assembly together is required. The aluminum rods are exceptionally sturdy and attractive in design.

By making the two sections each different depths the odd sized Whammy pedal as-well-as a power supply could fit onto the larger half. Standard sized pedals fit nicely on the small pedalboard. Power, signal, and LED wiring are all easily bundled together with wire ties between boards; no disconnecting of cables is needed. A continuous 45 degree, ½” chamfer was cut into the frame at the joined pedalboards’ center of mass to act as a handle. Milling the handle to be underneath meant that valuable real estate in the case could be used for guitar pedals instead of an external carrying handle. The entire system could be manufactured using available tools. Additional hardware was purchased for less than the cost of the wood. Meeting design requirements for the Dual Pedalboard proved to be challenging but the final product far exceded expectations.