January 19, 2021

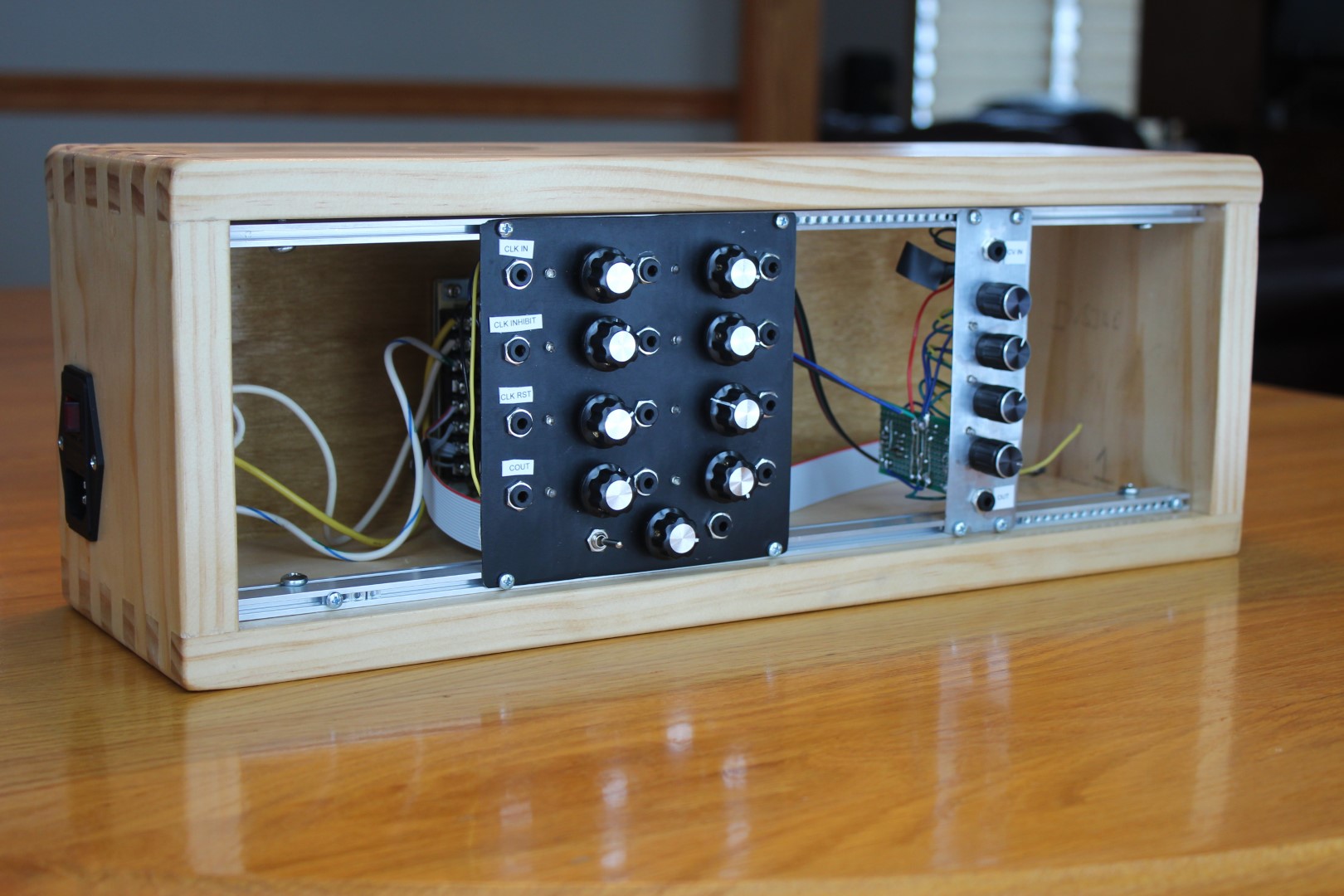

On Tuesday January 12th, I had an idea. Actually I had a lot of ideas while brainstorming new products for Jake’s Custom Shop. One, however, sounded particularly interesting. I decided to build a refined and fully equipped eurorack case to replace a simple one I built about a year back. The remainder of that Tuesday was spent designing, modeling and ordering components. With school starting back in just seven days a certain urgency propelled the project.

Preliminary designs for this tricked-out box kept reinforcing the necessity of a wood shop router table. I would need some sort of groove or rabbit cut to install the rear panel. I did this once before with a circular saw for my ATX power supply but it was difficult and messy. Box joints are something I’ve always liked and really wanted to implement. The solution? Build a router table out of scrap wood from around the shop.

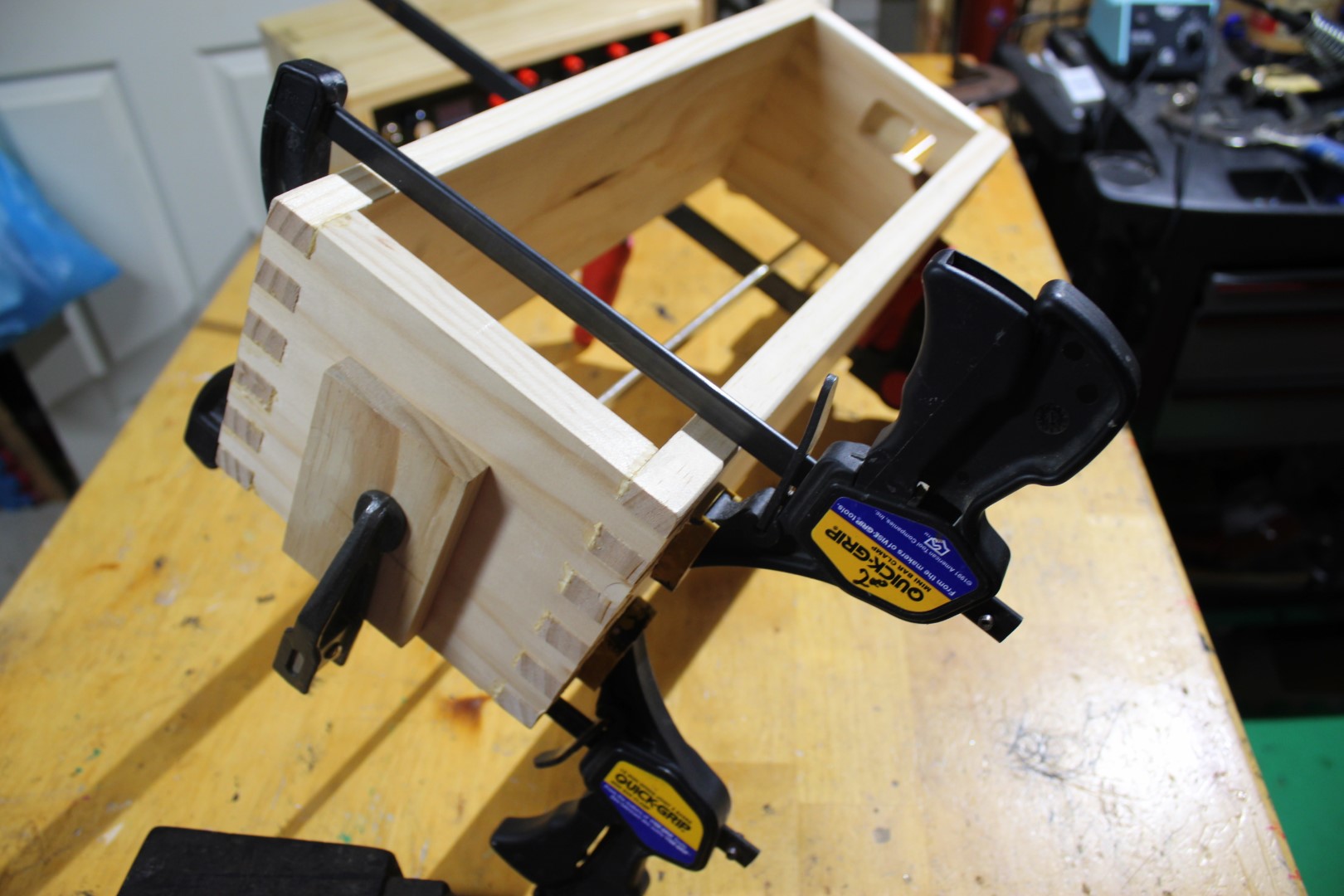

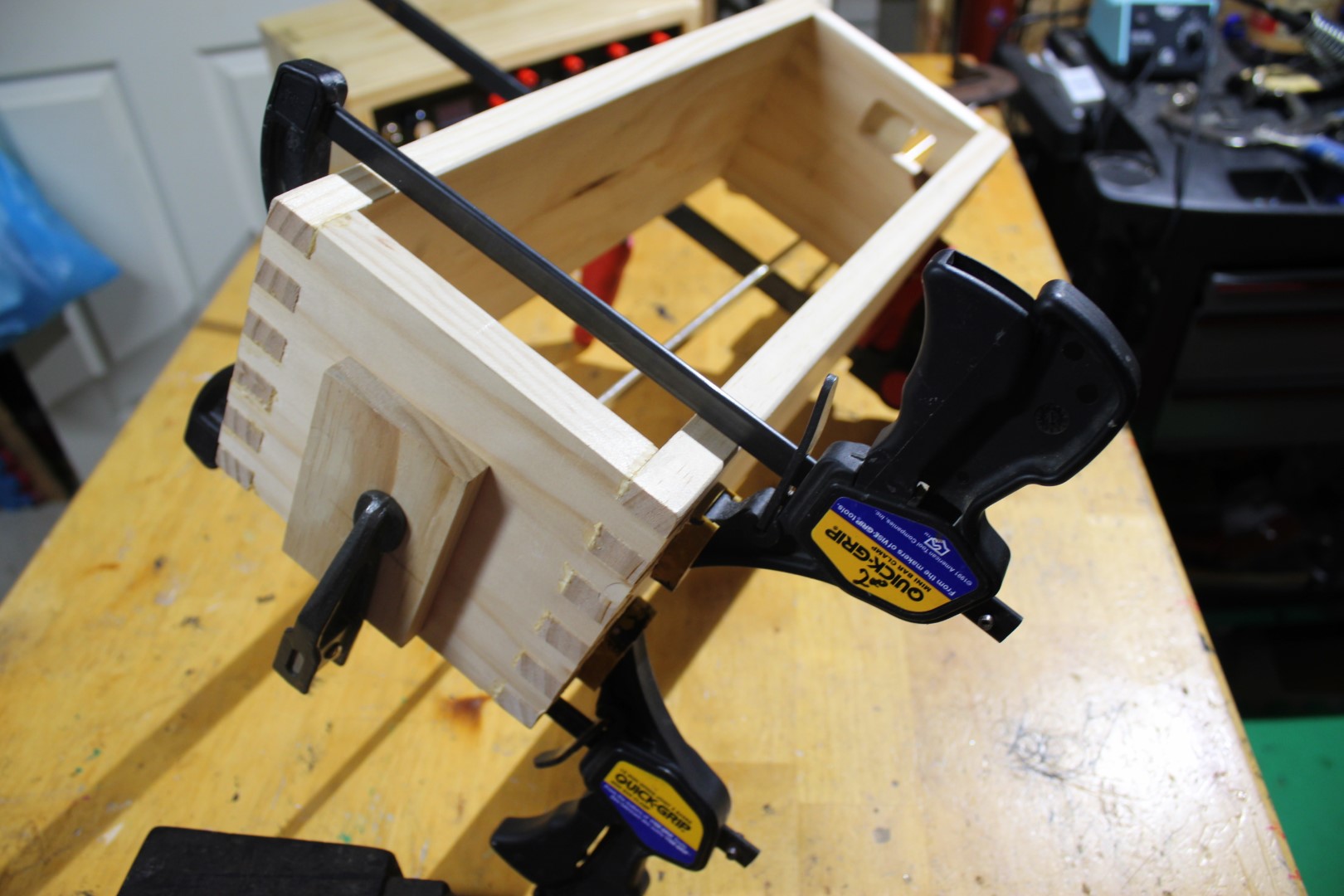

It took about two full days to go from scrap wood to a router table to tight fitting box joints. Most of that time was spent tuning my homemade box joint jig so that each “finger” was neither too tight nor too loose. I made at least two dozen box joint pairs before cutting the wood stock for the eurorack. Spending the extra time to get it right paid off. Everything fits tight without gaps or holes.

In order to get the back panel to sit flush with the edge of the box there is a rabbit cut for the plywood-back to sit in. This was made after glueing the box-joints. I had to get pretty creative with the router table to make an interior cut without ruining the piece. Next time it will be much easier to make the rabbit cut before assembling the box.

Inside the eurorack case is a 64 W power supply, flying bus bar, T-track and an AC power plug. These components make it easy to add or remove eurorack modules to the case without the need to run power from an external source. The image below was taken on January 18th, less than a week after I conceived the idea.

Placing a time constraint on this project was extremely insightful. Most of my big projects take many months to go from idea to reality. Adding the hard constraint of school required that I place my full attention to completion of the eurorack case. You instinctively work fast, avoid the unimportant, deny distractions and hasten other activities to focus on one. By focusing on one project you maintain a clear and defined goal that guides you through the process. Regularly makers find themselves lost in a long-term project because the next step is not obvious. Becoming fully involved in a time-constrained project clarifies the steps you must take. There is no time to slack off.